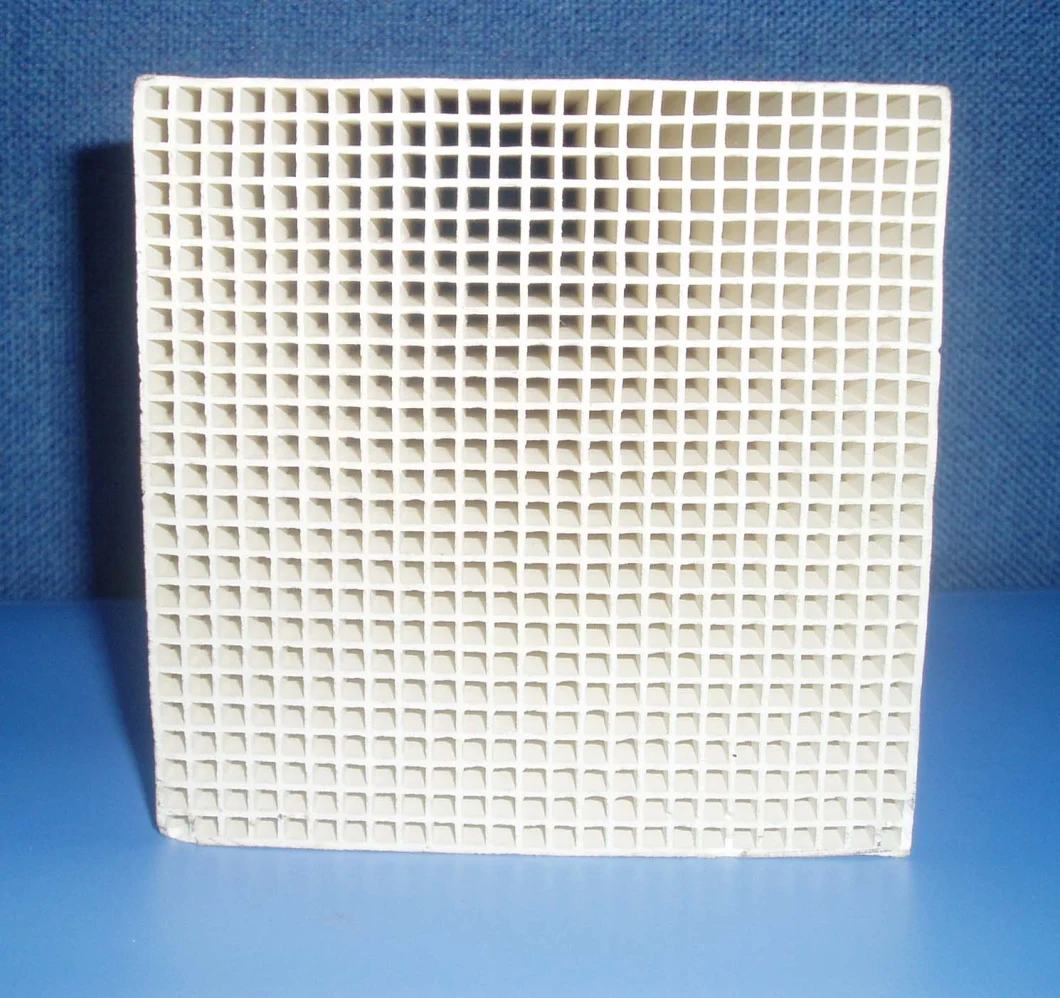

The honeycomb ceramic as heat exchange media is the key part for heat storage HTAC (High Temperature Air Combustion) technology, which has been widely applied in all kinds of pushing-steel heating furnace, RTO (Regenerative Thermal Oxidation), stepping heating furnace, heat treatment furnace, forging furnace, dissolving furnace, steel wrapping/middle wrapping baking apparatus, soaking pit, radiation tap incendiary apparatus, covering furnace, high temperature hot-blast stove in metallurgical machine building and all kinds of ceramic cellar stove, glass cellar stove in building materials, and all kinds of tap heating stove, splitting stove, other industrial stove cellar, too.

Honeycomb ceramics as heat storage body, by the advantage of large specific surface area, small heat resistance, good thermal conductivity, excellent thermal shock resistance, realize quickly exchanging heat; reducing energy in the strict sense (up to 97% of true thermal energy can be recovery and also it can absorb NOx more than 40%).

Features:

1.Bare high temperature

2.Heat exchange medium

3.Large specific surface area

4.Environment protecting

| Name | Alumina | Dense Cordierite | Porous Cordierite | Cordierite-Mullite | Dense Alumina | Mullite | ||||||||

| Density(g/cm3) | 2.0~2.3 | 2.1 ~2.5 | 1.5 ~1.9 | 1.8~2.3 | 2.4 ~2.7 | 2.0 ~2.5 | ||||||||

| Coefficient of heat expansion (×10-6K-1) (20~800Celsius Degree) | ≤5 | ≤3.5 | ≤3.0 | ≤3.5 | ≤5 | ≤5 | ||||||||

| Specific Heat (J/Kg.K)(20~1000Celsius Degree) | 900~1150 | 900~1100 | 900~1100 | 900~1150 | 1000~1150 | 1000~1150 | ||||||||

| Thermal Conductivity (W/m.k) (20~1000Celsius Degree) | 1.5~2.0 | 1.5~2.5 | 1.2~1.8 | 1.5~2.0 | 1.5~2.5 | 1.5~2.0 | ||||||||

| Impact Thermal Resistance (Celsius Degree) | ≥300 | ≥300 | ≥350 | ≥350 | ≥300 | ≥350 | ||||||||

| Max. Working Tem.(Celsius Degree) | 1350 | 1300 | 1300 | 1320 | 1350 | 1450 | ||||||||

| water absorption(%) | 15-25 | ≤2 | 15~25 | 15 ~25 | ≤2 | 15~25 | ||||||||

| compressive strength(MPa) | ≥28 | ≥28 | ≥25 | ≥25 | ≥28 | ≥28 | ||||||||

| chemical composition (%) | Al2O3 | 55 ~65 | 25 ~38 | 28 ~38 | 40~52 | 55 ~65 | 60 ~70 | |||||||

| SiO2 | 25~35 | 50 ~60 | 45 ~55 | 45 ~55 | 25 ~35 | 25 ~35 | ||||||||

| MgO | 1~3 | 5 ~10 | 11 ~14 | 7~9 | 3~5 | 0 ~1 | ||||||||

| others | <5 | <5 | <5 | <5 | <5 | <5 | ||||||||

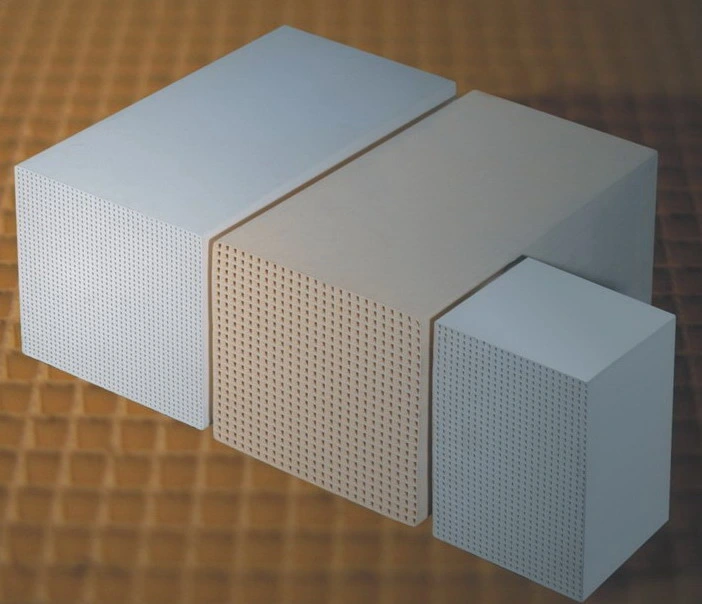

| Dimension (mm) | Quantity of cells | Wall thickness (mm) | Width of cell (mm) | Surface area (m2/m3) | Void section (%) | Weight per piece (kg) |

| 150*150*300 | 25*25 | 1 | 4.96 | 580 | 68 | 4.7 |

| 150*150*300 | 40*40 | 0.7 | 3.03 | 891 | 65 | 5.5 |

| 150*150*300 | 50*50 | 0.6 | 2.39 | 1090 | 63 | 6.1 |

| 150*150*300 | 60*60 | 0.5 | 1.99 | 1303 | 63 | 6.3 |

| 150*100*100 | 40*40 | 1 | 2.5 | 784 | 49 | 1.2 |

| 150*100*100 | 33*33 | 1.1 | 3 | 691 | 52 | 1.13 |

| 150*100*100 | 20*20 | 2 | 5 | 392 | 49 | 1.04 |

| 100*100*100 | 40*40 | 1 | 2.5 | 784 | 49 | 0.81 |

| 100*100*100 | 33*33 | 1.1 | 3 | 691 | 52 | 0.75 |

| 100*100*100 | 20*20 | 2 | 5 | 392 | 49 | 0.68 |